Development Blog #1: Introducing ShowIO

A clever escape artist enters the last code in a secret combination and triumphant music rings out as the final door of an escape room opens. A guest crosses the threshold of a room in a haunted house and triggers a flash of light as a skeleton jumps out to grab them. Children bounce around the floor of a museum, their steps magically illuminating spotlights on a painted map of the world.

Escape rooms, haunted houses, museums, theatre, concerts - whenever a show reacts to the physical world, or vice-versa, audiences are blown away. But the tools that entertainment technologists have to pull off this type of synchronized interactivity are limited at best and non-existent at worst.

This was the core problem that led us to start Show Technologies. Trevor was tired of paying top-dollar for industrial PLCs that didn't play nice with show systems, and I was tired of hacking together Arduino monstrosities that needed constant debugging and rewiring. If we wanted to get a lightboard or sound system to open a solenoid valve or respond to a breakbeam sensor, we were always forced to spend too much money or time to cobble together one-off systems that worked *well enough* at best.

We were itching for a device that was as easy to integrate with a show control system as a remote I/O box is to integrate with a PLC, but nothing out there checked all of our boxes - fast two-way show control communication, modularity to scale, and rugged reliability. So we built it ourselves!

(After four rounds of prototypes, countless design revisions, and two years of development. But the road we took to get here is a topic for another time).

Through this series, I want to share the insights we've found throughout the development cycle of ShowIO, our flagship hardware platform, leading up to our product launch at the beginning of next year. And I hope that these posts will spur some community discussion that, in turn, influences our design decisions down the road. For this first installment, I'd like to give a quick intro to ShowIO and show off our capabilities.

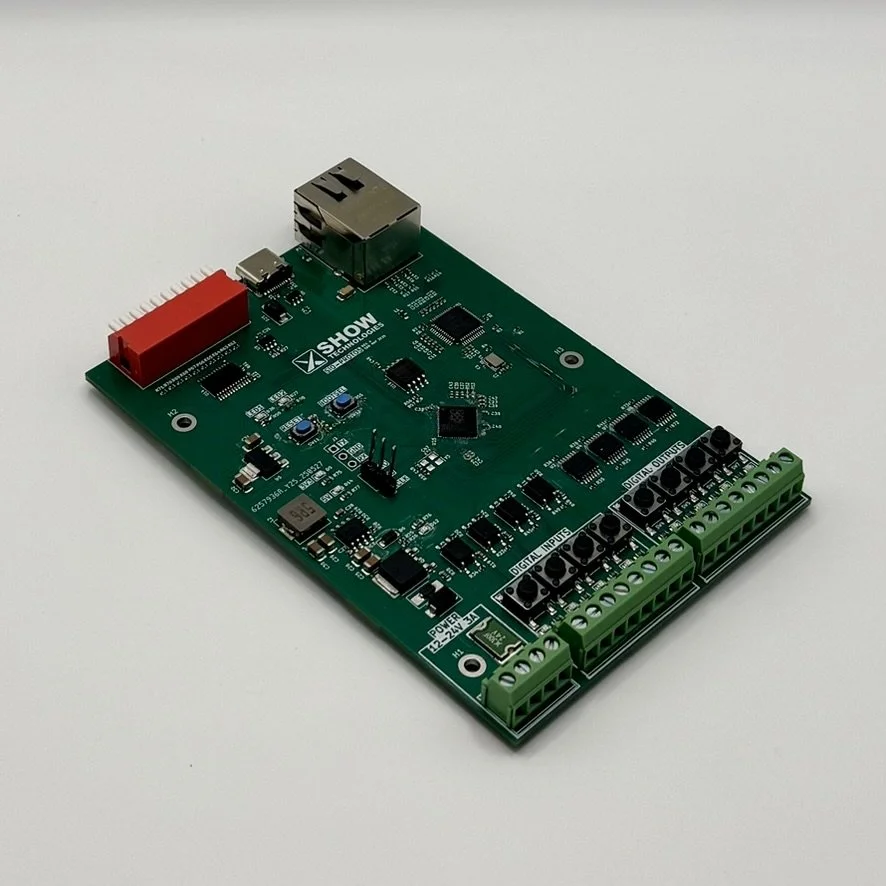

ShowIO PROTO5 development board

This is the ShowIO PROTO5; it's our current-generation prototype PCB and about 90% of the way to being a product ready for launch. It's designed to fill the void between a PLC and an Arduino in live entertainment control hardware by allowing users to control industrial digital inputs and digital outputs directly from their show control systems - here's a rundown of what it can do.

OSC over Ethernet

ShowIO is designed from the ground up with OSC (Open Sound Control) as our core communication standard. OSC is fast, simple, flexible, and basically every live entertainment control platform speaks it. This makes it a great backbone for a product that needs to communicate data flexibly and efficiently while remaining compatible with a wide range of control systems. A 10/100 Ethernet link offers a reliable wired connection to a show network, and familiar DIP switches allow quick local IP address configuration.

Digital I/O

PROTO5 has 4 digital outputs, which can be used to drive relays, solenoids, valves, electromagnets, DC motors, or anything else that runs on 12- or 24-volt power and draws less than 2 amps. Connect any medium-power DC device to PROTO5 to make it part of your show! Additionally, there are 4 digital inputs, which can turn on/off signals from buttons and sensors into OSC messages. Hook up a pushbutton, breakbeam sensor, capacitive touch switch, or anything else that outputs a 12- to 24-volt signal, and use it to trigger cues on your show controller. We've also included some handy pushbuttons that allow an electrical test of any inputs and output signals before your device is even hooked up to the network, and LED indicators that show the status of each I/O point.

Circuit Protection

There's nothing we hate more than having a show-critical device crap out on us in the middle of a show. Actually, scratch that - making a wiring mistake trying to get an effect working at the eleventh hour and killing a board with a dead-short is a pretty close second. Reliability and ruggedness are huge points of emphasis in our hardware design. We've sourced quality components with plenty of overhead for the rated operating parameters to keep your show running night after night, and added failsafe measures like resettable fuses, ESD protection, reverse voltage protection, and current-limited drivers to ensure that a midnight mistake doesn't let the magic smoke out of the box.

I think that'll wrap it up for this week's update - If you've made it this far, I hope you got a good picture of what we're doing at Show Technologies. If you have any thoughts, or if you're interested in joining our Early Adopter Program to get your hands on beta products, feel free to shoot me an email directly at sdick@show-technologies.com.